Make to order

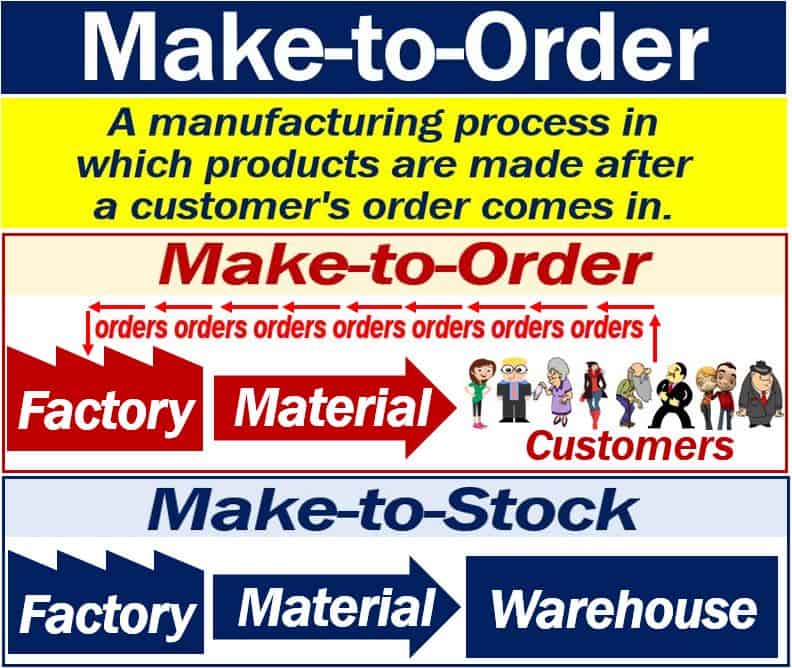

It is also referred to as build to order and focuses mainly on production approach. It is a business strategy that allows consumers to purchase products that are tailored to their stipulation. This is made by manufactures only to create additional wait time for the consumer to receive the product, but allows for more elastic customization compared to purchasing from retailers shelves (Rafiei et al, 2011).

This strategy relieves the troubles of extreme inventory that is common with the customary make to stock strategy. This strategy involves a high level of customer involvement. Examples of make to order are; Criminal legal defense, auto repair, medical services, progression of a business bookkeeping system, and tailoring.

Assemble to order

This strategy requires that the essential parts of the product are already manufactured but not yet assembled. Once an order is established, the parts are assembled and sent to the customer. Assemble to order is a fusion between a make to stock strategy where products are wholly produced in advance and the make to order strategy where products are manufactured once the order has been acknowledged.

Assemble to order strategy attempts to join the reimbursement of both strategies receiving products into customers’ hands fast, while allowing for the product to be customizable. Advantages of this method are that businesses can condense errors in the release of products. Examples of assemble to order are; Repair-kit problem, computers, printers and toners, order fulfillment at e-commerce retailers and mail order catalog (Benjaafar 2006),

Make to stock

It is a business strategy used by businesses to counterpart production with customer order estimate. It forecasts demand to establish how much stock to produce (Zeng et al, 2013). The major disadvantage of this method is that it relies on the exactness of order forecasts. Inexact forecasts will pilot to fatalities stemming from extreme inventory or stocks. Examples are mass steel production,

Advantages of make to stock over assemble to order and made to order

The projected approach gets the judgment maker to benefit from the strategy. The procedure of manufacturing in make to stock process environment adds the assessment of the products through mixing, unraveling, forming, machining, and chemical processes. Make to stock products are particularly to be shipped from accomplished goods, are fulfilled prior to the post of the customer order, and usually created in accordance to sales.

References

Stevenson*, M., Hendry, L. C., & Kingsman†, B. G. (2005). A review of production planning and control: the applicability of key concepts to the make-to-order industry. International journal of production research, 43(5), 869-898.

Benjaafar, S., & ElHafsi, M. (2006). Production and inventory control of a single product assemble-to-order system with multiple customer classes. Management Science, 52(12), 1896- 1912.

Zeng, M. X., Ouyang, W., & Zhen, Z. Q. (2013). Application of GM (1, 1) Model to Production Demand Forecast for Make-to-Stock Enterprise. Advanced Materials Research, 823, 602- 605.

Olhager, J., & Prajogo, D. I. (2012). The impact of manufacturing and supply chain improvement initiatives: A survey comparing make-to-order and make-to-stock firms. Omega, 40(2), 159-165.

Zhang, Z. G., Kim, I., Springer, M., Cai, G. G., & Yu, Y. (2013). Dynamic pooling of make-to- stock and make-to-order operations. International Journal of Production Economics, 144(1), 44-56.

Cheng, T. C. E., Gao, C., & Shen, H. (2011). Production and inventory rationing in a make-to- stock system with a failure-prone machine and lost sales. Automatic Control, IEEE Transactions on, 56(5), 1176-1180.

Rafiei, H., & Rabbani, M. (2011). Order partitioning and order penetration point location in hybrid make-to-stock/make-to-order production contexts. Computers & Industrial Engineering, 61(3), 550-56